Solution based on a renting model

Comprehensive financing service for 10-year operations, all-inclusive except real estate and supply infrastructure.

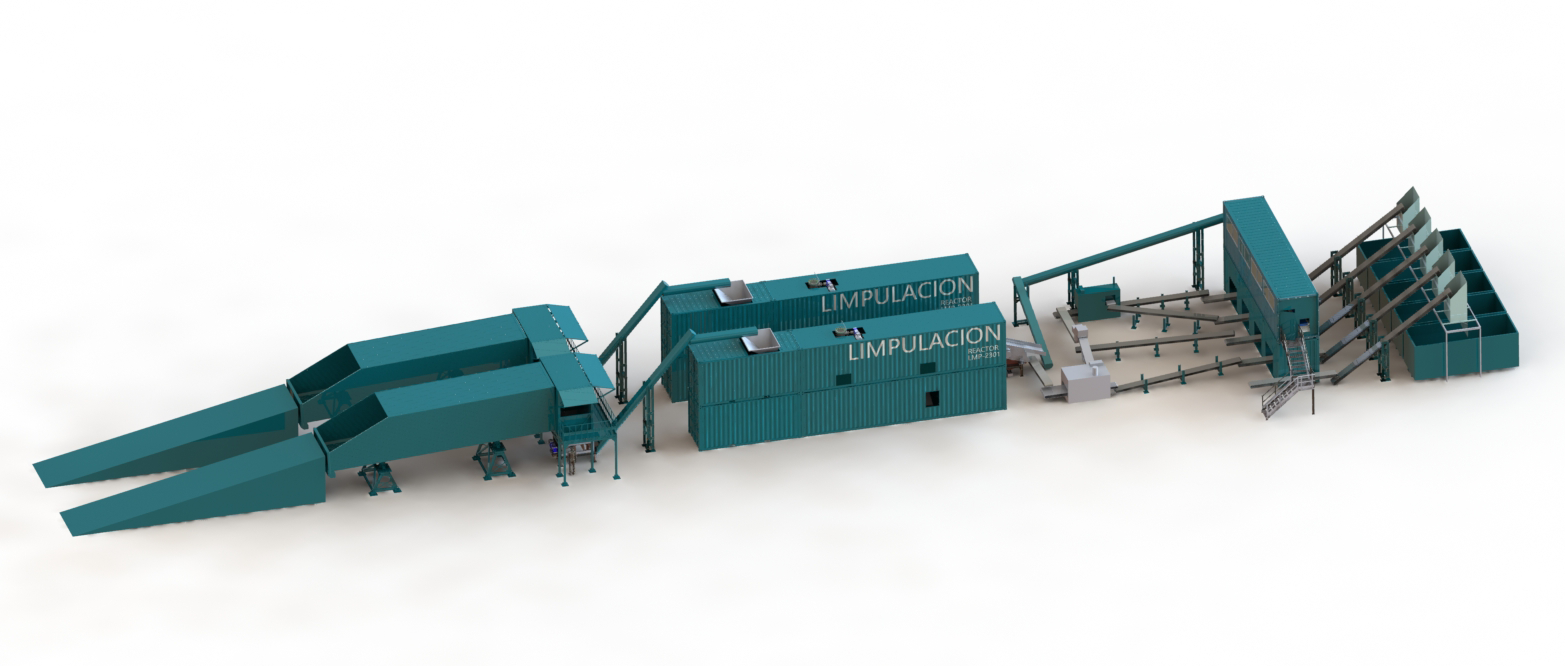

Thermowaste has developed a concept of modular and pre-engineered plants so that the equipment can be quickly and easily transported and installed anywhere in the world.

Space optimization.

Quick to build and start up.

Economy of scale.

Process lines working in parallel.

Easy to transport and install worldwide.

After years of research, Thermowaste’s engineering team launches a new biotechnology solution based on the continuous process of Limpulación®, which by applying steam cleans, sterilizes and morphologically transforms the waste, facilitating its subsequent classification.

CLEARANCE GAUGE CONTROL

Municipal solid waste (MSW), commercial, industrial and hospital waste assimilated to municipal waste, as well as rejects from other MSW sorting processes are received, and bulky and hazardous waste is discarded. The remaining unsorted waste is passed on to the next stage of the process.

LIMPULACIÓN

The waste enters directly into the Thermowaste reactors, where it is processed for 30 minutes. During this time, the waste is converted into clean and manipulable materials.

CLASSIFICATION AND EXPEDITION

Recovered materials are easily sorted automatically, semi-automatically or manually.

Once cleaned and sorted, all materials are reintroduced into the market through various valorization routes studied and adapted to the opportunities of each region.

When the waste arrives at the plants designed by Thermowaste, it is submitted to the process of Limpulación® , where it is morphologically transformed and converted into clean and manipulable materials, free of pathogens and bad odors. The waste is never visible, and all the personnel work in safe and sanitary conditions.