day

We offer a complete solution to end landfills.

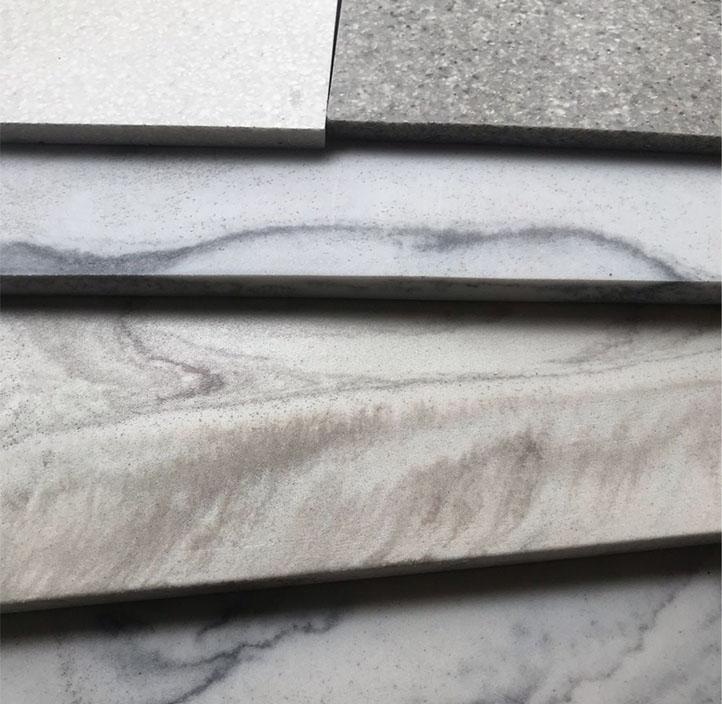

A sustainable and definitive solution that accelerates social transformation towards a Circular Economy. We convert municipal solid waste into clean materials and recover them in their entirety to give them a second use, at the same time that we provide decent work to many families.

Viruses, leachates, fires, CO2 and methane gas emissions, the landfills are a serious problem on our planet.